Engineering Guide to Aluminum Pipes and Tubes (2026 Edition)

You are facing a critical weight-to-strength ratio bottleneck in your latest offshore skid design, or perhaps your stainless steel lines are showing unexpected chloride stress corrosion. Why settle for over-engineered, heavy solutions when Aluminum Pipes and Tubes offer the precise thermal conductivity and corrosion resistance your project demands? In this guide, we break down the metallurgical selection and ASTM standards required for modern 2026 infrastructure.

Key Engineering Takeaways

- Alloy Optimization: Understand why 6061-T6 is the gold standard for structural integrity while 5000-series excels in marine environments.

- Regulatory Compliance: Stay updated on the 2026 ASTM B210 and B241 specifications for seamless versus structural tubing.

- Cost Efficiency: Learn how the 33% weight reduction compared to steel translates to lower logistics and installation labor costs.

At a Glance: Aluminum Pipes and Tubes

Aluminum Pipes and Tubes are lightweight, corrosion-resistant conduits used in aerospace, marine, and cryogenic industries. Unlike steel, aluminum forms a protective oxide layer, making it ideal for harsh environments. Selection is governed by ASTM B241 (pipe) and B210 (tube), focusing on alloy temper (e.g., T6) and pressure ratings.

Founder’s Engineering Insight

“In my 20 years of piping design, the most common mistake is treating aluminum like carbon steel during the thermal expansion calculation. Aluminum expands nearly twice as much as steel; if you don’t design your loops specifically for Aluminum Pipes and Tubes, you’re inviting fatigue failure at the joints.”

— Atul Singla

Technical Roadmap

Complete Course on

Piping Engineering

Check Now

Key Features

- 125+ Hours Content

- 500+ Recorded Lectures

- 20+ Years Exp.

- Lifetime Access

Coverage

- Codes & Standards

- Layouts & Design

- Material Eng.

- Stress Analysis

Aluminum Pipes and Tubes Competency Quiz

Validate your engineering knowledge for 2026 standards

1. Which ASTM standard specifically governs “Seamless Aluminum and Aluminum-Alloy Drawn Tube”?

Aluminum Pipes and Tubes vs. Steel: A Comparative Performance Analysis

When evaluating Aluminum Pipes and Tubes against traditional carbon or stainless steel, engineers must look beyond initial material costs. The primary advantage of aluminum lies in its exceptional strength-to-weight ratio. Aluminum is approximately one-third the weight of steel, which drastically reduces the structural load on pipe racks and support systems. In 2026, as modular construction and offshore efficiency become paramount, this weight reduction translates directly into lower shipping costs and faster onsite installation without the need for heavy lifting equipment.

Furthermore, Aluminum Pipes and Tubes exhibit superior low-temperature performance. While many carbon steels become brittle and prone to catastrophic failure at sub-zero temperatures, aluminum alloys actually increase in tensile strength and ductility. This makes them the definitive choice for cryogenic applications and LNG (Liquefied Natural Gas) transport. In terms of corrosion, aluminum’s natural ability to form a tenacious, self-healing oxide film provides a maintenance-free lifespan in atmospheric and many chemical environments where steel would require expensive multi-layer coating systems.

Common Alloys Used in Industrial Aluminum Pipes and Tubes

Selecting the correct alloy for Aluminum Pipes and Tubes is critical for ensuring mechanical longevity. The industry typically categorizes these into several series based on their alloying elements:

- 6061-T6 (The Structural Standard): Magnesium and silicon are the primary elements. This alloy offers excellent weldability and structural strength. It is the most versatile choice for high-pressure Aluminum Pipes and Tubes used in heavy-duty frameworks.

- 5083 / 5086 (The Marine Specialists): These magnesium-alloyed grades are renowned for their exceptional resistance to seawater and salt-spray corrosion. They are frequently specified for Aluminum Pipes and Tubes in shipbuilding and offshore platforms.

- 3003 (The General Purpose Grade): Alloyed with manganese, 3003 provides moderate strength with excellent workability. It is widely used in HVAC systems and heat exchangers where Aluminum Pipes and Tubes must be bent or formed.

- 6063 (The Architectural Choice): Often referred to as the architectural alloy, it provides a smoother surface finish and is ideal for Aluminum Pipes and Tubes used in visible handrails or decorative structural elements.

Critical Aluminum Pipes and Tubes Codes and Standards (ASTM/ASME)

Compliance with international standards ensures that Aluminum Pipes and Tubes can withstand the design pressures and environmental stresses of industrial service. In 2026, the primary governing documents remain:

| Standard | Scope / Application |

|---|---|

| ASTM B241 | Standard Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube. |

| ASTM B210 | Covers Seamless Aluminum and Aluminum-Alloy Drawn Tubes for general purpose and pressure applications. |

| ASME B31.3 | The Process Piping code that dictates the allowable stresses and design rules for Aluminum Pipes and Tubes. |

| ASTM B221 | Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes. |

Dimensional Specifications for Aluminum Pipes and Tubes

Understanding the sizing conventions for Aluminum Pipes and Tubes is vital for ensuring system compatibility. Pipes follow the Nominal Pipe Size (NPS) system, where the Schedule (e.g., Sch 40 or Sch 80) determines the wall thickness relative to a constant Outer Diameter (OD). Conversely, Tubes are measured by their actual Outside Diameter and Wall Thickness (often in inches or millimeters).

| NPS (Inches) | Outside Diameter (OD) | Sch 40 Wall (in) | Weight (lb/ft) |

|---|---|---|---|

| 1/2″ | 0.840″ | 0.109″ | 0.294 |

| 1″ | 1.315″ | 0.133″ | 0.581 |

| 2″ | 2.375″ | 0.154″ | 1.264 |

| 4″ | 4.500″ | 0.237″ | 3.733 |

Engineering Parameters for Choosing Aluminum Pipes and Tubes

When specifying Aluminum Pipes and Tubes for 2026 industrial projects, engineers must evaluate three core pillars: Geometry, Pressure, and Thermal Loading.

The Shape of Aluminum Tubing & Piping

Unlike steel, which is predominantly circular, Aluminum Pipes and Tubes are frequently extruded into square, rectangular, and streamlined aerodynamic shapes. In structural frames, square tubing provides higher torsional rigidity, while elliptical profiles are utilized in high-velocity heat exchangers to minimize air-side pressure drop.

Process Parameters and Thermal Conductivity

Aluminum’s thermal conductivity is roughly 235 W/m·K, nearly four times higher than carbon steel. This makes Aluminum Pipes and Tubes the primary candidate for heat transfer equipment. However, the design must account for the Allowable Stress drop-off as temperatures exceed 150°C (300°F), as defined in ASME B31.3 Table A-1.

Mechanical Characteristic Features of Aluminum Pipes and Tubes

The defining characteristic of Aluminum Pipes and Tubes is their ability to maintain ductility at cryogenic temperatures. Unlike ASTM A106 carbon steel, which undergoes a ductile-to-brittle transition, aluminum’s face-centered cubic (FCC) crystal structure prevents low-temperature embrittlement.

Surface Finish Options for Aluminum Pipes and Tubes

In 2026, surface treatment for Aluminum Pipes and Tubes is no longer just aesthetic; it is a functional requirement for wear resistance:

- Mill Finish: The natural “as-extruded” surface, suitable for hidden structural components.

- Anodized (Type II & III): An electrochemical process that thickens the natural oxide layer, reaching hardness levels comparable to tool steel.

- Powder Coating: Provides a secondary dielectric barrier and UV protection for outdoor Aluminum Pipes and Tubes.

- Bright Dipped: A chemical polishing process used for high-reflectivity applications in lighting or laboratory environments.

Aluminum Pipes and Tubes Fittings and Connection Components

Joining Aluminum Pipes and Tubes requires specialized fittings to prevent galvanic corrosion. When connecting to dissimilar metals (like copper or steel), use dielectric isolators. Standard connection methods include:

TIG/MIG Welding

Utilizing 4043 or 5356 filler wire to ensure joint chemistry matches the parent Aluminum Pipes and Tubes.

Compression Fittings

Ideal for small-diameter Aluminum Pipes and Tubes in instrumentation, eliminating the need for hot work.

Victaulic Grooving

Mechanical coupling systems that allow for rapid assembly and accommodate thermal expansion/contraction.

Aluminum Pipes and Tubes: Internal Pressure Calculator

Estimate the Internal Design Pressure (P) using Barlow’s Formula for 2026 Engineering Specs.

Don’t miss this video related to Aluminum Pipe

Summary: Master Piping Engineering with our complete 125+ hour Certification Course: ……

Aluminum Pipes and Tubes Failure Case Study: Marine Infrastructure Analysis

Project Overview: Coastal Fuel Transfer Terminal

In 2024, a fuel terminal located in a high-salinity coastal zone reported frequent leaks in their secondary containment lines. These lines originally utilized galvanized Aluminum Pipes and Tubes (6063-T6) but were failing prematurely at the connection points to stainless steel pumps.

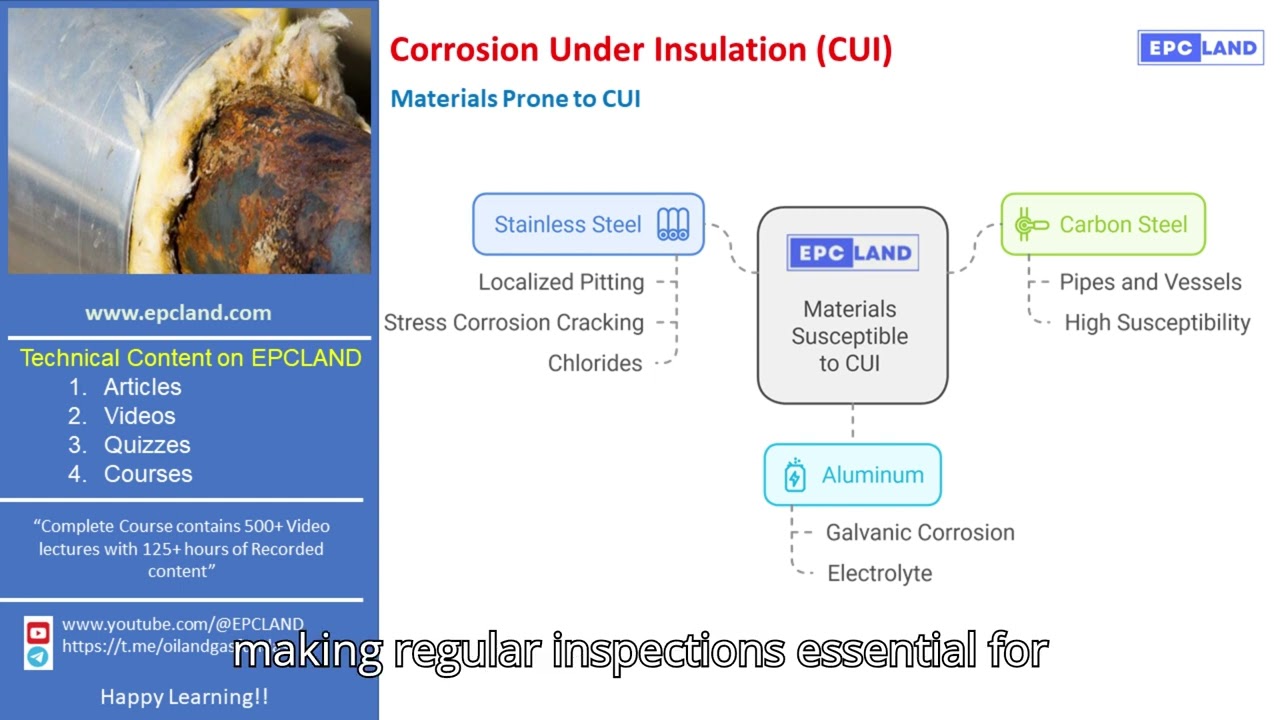

The Failure Mechanism: Galvanic Corrosion

Engineering forensic analysis identified galvanic corrosion as the root cause. Because Aluminum Pipes and Tubes are more anodic than stainless steel, the presence of saltwater acted as an electrolyte, causing the aluminum to sacrifice itself at the interface. This resulted in severe pitting and wall thinning within 18 months of service.

The 2026 Rectification Strategy:

- Isolation: Installation of PTFE-lined dielectric flange kits to electrically isolate the Aluminum Pipes and Tubes from the stainless steel machinery.

- Alloy Upgrade: Transitioned the most exposed sections to 5083-H116 alloy, which offers superior magnesium-based resistance to chloride-induced pitting.

- Monitoring: Implemented ultrasonic thickness (UT) testing every 6 months to track the oxide layer health.

Conclusion: While Aluminum Pipes and Tubes offer incredible corrosion resistance in isolation, they must be engineered with strict adherence to the galvanic series when integrated into multi-metal systems.

Expert Insights: Lessons from 20 years in the field

-

1

Differentiate by Temper: Never specify Aluminum Pipes and Tubes by alloy alone. A 6061-O (annealed) pipe has less than half the yield strength of 6061-T6. The temper is what defines your pressure rating.

-

2

Welding Heat Zones: Remember that welding Aluminum Pipes and Tubes creates a Heat Affected Zone (HAZ) that can reduce the local strength by up to 40%. Always use the reduced “as-welded” allowable stress values from ASME B31.3 for your calculations.

-

3

Storage is Critical: Water trapped between stacked Aluminum Pipes and Tubes during storage causes “white rust” (water staining). Store pipes at an incline or indoors to maintain the 2026 premium mill finish.

Frequently Asked Questions

Are Aluminum Pipes and Tubes suitable for potable water systems? ↓

How do I prevent galvanic corrosion in Aluminum Pipes and Tubes? ↓

What is the difference between B241 and B210 standards? ↓

Can I use standard steel hangers for Aluminum Pipes and Tubes? ↓

Why is my aluminum pipe showing carryover in pneumatic systems? ↓

Is 6061-T6 the best choice for sub-zero LNG applications? ↓

📚 Recommended Resources: Aluminum Pipes

Read these Guides