What Will You Do if Carbon Steel Pipe is Installed in Place of LTCS: Carbon Steel vs LTCS Pipe Substitution Guide

The technical distinction between Carbon Steel vs LTCS Pipe is a critical safety factor in cryogenic and low-temperature processing environments. In 2026, engineering integrity remains paramount; substituting standard carbon steel for Low Temperature Carbon Steel (LTCS) without proper stress ratio analysis can lead to catastrophic brittle fracture. This guide explores the regulatory framework for managing such material mix-ups.

Executive Summary: Carbon Steel vs LTCS Pipe Substitution

If standard Carbon Steel (e.g., A106-B) is incorrectly installed instead of LTCS (e.g., A333-6), engineers must evaluate the Minimum Design Metal Temperature (MDMT). Under ASME B31.3, a material may be used below its curve temperature if the stress ratio is less than 1.0, allowing for significant MDMT reductions without impact testing.

Technical Competency Quiz: LTCS Requirements

Question 1 of 5Quiz Completed!

Complete Course on

Piping Engineering

Check Now

Key Features

- 125+ Hours Content

- 500+ Recorded Lectures

- 20+ Years Exp.

- Lifetime Access

Coverage

- Codes & Standards

- Layouts & Design

- Material Eng.

- Stress Analysis

Identifying the Root Cause: Why Carbon Steel vs LTCS Pipe Mix-ups Occur

In complex industrial projects during 2026, the logistical handling of piping materials remains a significant risk factor. The confusion between Carbon Steel vs LTCS Pipe typically stems from the physical similarity of the materials. Standard carbon steel, such as ASTM A106 Grade B or A53 Grade B, looks nearly identical to Low Temperature Carbon Steel (LTCS), such as ASTM A333 Grade 6, to the naked eye.

Mix-ups often occur during the procurement or warehousing phase where color-coding systems fail or stenciling becomes obscured. Because both materials are technically "carbon steels," personnel without specific metallurgical training may assume they are interchangeable. However, the lack of grain refinement and specific alloying elements in standard carbon steel makes it susceptible to sudden, catastrophic failure when exposed to temperatures below its designed threshold.

Immediate Engineering Actions: What to Do if Carbon Steel vs LTCS Pipe is Swapped

Once a discrepancy in Carbon Steel vs LTCS Pipe application is identified, the engineering team must follow a strict protocol governed by ASME B31.3 or local jurisdictional codes. The first step is a complete isolation of the affected system and a verification of all Material Test Reports (MTRs) for the batch in question.

- Verify Material Grade: Perform Positive Material Identification (PMI) to confirm the chemical composition, focusing on Silicon and Manganese levels which differ between A106 and A333.

- Review MDMT: Identify the actual Minimum Design Metal Temperature (MDMT) of the process fluid compared to the material's rated temperature.

- Impact Test Review: Check if the installed standard carbon steel underwent any supplemental Charpy V-Notch testing at the mill.

The Role of Stress Ratio in Evaluating Carbon Steel vs LTCS Pipe Safety

When evaluating a Carbon Steel vs LTCS Pipe substitution, the Stress Ratio (SR) is the most powerful tool in an engineer's arsenal. Under ASME B31.3 Paragraph 323.2.2, if a pipe is operating significantly below its design pressure, it is under-stressed. This lack of stress allows the material to behave more predictably even at lower temperatures.

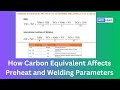

Calculating the MDMT Reduction Using ASME B31.3 Standards

The Stress Ratio is defined as the ratio of the design pressure at the MDMT to the maximum allowable pressure at that temperature. In 2026, automated FEA and piping stress software simplify this calculation, but the fundamental principle remains: if the stress ratio is less than 1.0, a temperature reduction (offset) can be applied to the material's curve temperature.

| Stress Ratio (SR) | MDMT Reduction Allowed | Example Outcome for A106-B |

|---|---|---|

| 1.0 | 0 Degrees C Reduction | Safe down to -29 Degrees C |

| 0.8 | 10 Degrees C Reduction | Safe down to -39 Degrees C |

| 0.4 | 55 Degrees C Reduction | Safe down to -84 Degrees C |

Don't miss this video related to Carbon Steel vs LTCS Pipe

Summary: Master Piping Engineering with our complete 125+ hour Certification Course: ......

Technical Comparison: Material Property Differences between Carbon Steel vs LTCS Pipe

Understanding the metallurgical variance in Carbon Steel vs LTCS Pipe is essential for justifying a substitution. While both materials are iron-based, the manufacturing process for Low Temperature Carbon Steel (LTCS) includes specific steps to ensure ductility at sub-zero temperatures. In 2026, the use of ASTM A333 Grade 6 remains the industry standard for these demanding conditions.

Impact Testing and Ductile-to-Brittle Transition Temperature (DBTT)

The primary differentiator for Carbon Steel vs LTCS Pipe is the Charpy V-Notch impact requirement. Standard carbon steel undergoes a transition from ductile to brittle behavior as temperatures drop. LTCS is designed to have a much lower Ductile-to-Brittle Transition Temperature (DBTT), ensuring the material can absorb energy and deform rather than shattering under impact at cryogenic levels.

Chemical Composition and Grain Refinement in Low Temperature Carbon Steel

To achieve low-temperature toughness, LTCS typically utilizes a "fine-grain" practice. This is often achieved through the addition of Aluminum or Silicon during the killing process in the steel mill. Standard Carbon Steel vs LTCS Pipe comparisons show that LTCS maintains a more controlled Manganese-to-Carbon ratio to optimize weldability and toughness.

| Property | Standard CS (ASTM A106-B) | LTCS (ASTM A333-6) |

|---|---|---|

| Impact Testing | Not Required (unless specified) | Mandatory at -45 Degrees C |

| Deoxidation | Killed | Fully Killed, Fine Grain |

| Carbon (Max) | 0.30 percent | 0.30 percent |

| Manganese | 0.29 to 1.06 percent | 0.29 to 1.06 percent |

Engineering Formula: Stress Ratio Calculation

As per ASME B31.3 Section 323.2.2:

Where:

r = Stress Ratio

Smax = Maximum circumferential pressure stress at MDMT

S = Allowable stress value from Table A-1

E = Quality factor

W = Weld joint strength reduction factor

Resolution Strategies: Risk-Based Inspection for Carbon Steel vs LTCS Pipe Errors

If the evaluation of Carbon Steel vs LTCS Pipe determines that the stress ratio is insufficient to lower the MDMT to safe levels, engineers in 2026 typically employ one of three strategies:

- In-Situ Impact Testing: If a sample can be safely extracted from a sacrificial component of the same heat, it can be tested to verify if the standard carbon steel naturally meets LTCS toughness requirements.

- Operating Envelope Modification: Restricting the minimum temperature or maximum pressure of the process to ensure the material remains within the safe ASME curve.

- Physical Replacement: If the risk of brittle fracture exceeds the facility's Risk-Based Inspection (RBI) threshold, the standard carbon steel must be replaced with certified ASTM A333 Grade 6 pipe.

Case Study: Rectifying a Carbon Steel vs LTCS Pipe Substitution in a Cryogenic Unit

Project Data

In early 2026, during the commissioning phase of a nitrogen header at a Gulf Coast petrochemical facility, a QC inspector flagged 150 meters of piping stenciled as ASTM A106 Grade B. The isometric drawings strictly required ASTM A333 Grade 6 (LTCS) due to a Minimum Design Metal Temperature (MDMT) of -40 Degrees Celsius.

- Line Service: Low-pressure Nitrogen Vapor

- Design Pressure: 150 PSIG

- Operating Temperature: -35 Degrees Celsius

- Material Installed: Carbon Steel (A106-B)

Failure Analysis

The engineering team identified that standard Carbon Steel vs LTCS Pipe properties vary significantly at -40 Degrees Celsius. A106 Grade B is typically rated for -29 Degrees Celsius. At -40 Degrees Celsius, the standard carbon steel was in the "lower shelf" of the Charpy impact curve, making it vulnerable to brittle fracture even from minor mechanical shocks or thermal transients.

Engineering Fix & Resolution

Instead of immediate replacement, which would have cost 85,000 USD in labor and schedule delays, the lead piping engineer performed a Stress Ratio analysis. The calculation revealed a ratio of 0.35 because the pipe was oversized for the low-pressure service. Under ASME B31.3 Figure 323.2.2B, a ratio of 0.35 allowed an MDMT reduction of 55 Degrees Celsius.

The adjusted MDMT for the A106-B pipe became -84 Degrees Celsius (-29 minus 55). Since the process MDMT was only -40 Degrees Celsius, the installed pipe was technically safe for continued service.

Lessons Learned

- Always verify stenciling during the receiving inspection to prevent Carbon Steel vs LTCS Pipe mix-ups before installation.

- Leverage ASME B31.3 stress ratio allowances to avoid unnecessary material replacement costs when safety margins permit.

- Update the facility Asset Integrity Management system to reflect the specific MDMT reduction applied to these assets for future 2026 audits.

Frequently Asked Questions: Carbon Steel vs LTCS Pipe

Can standard Carbon Steel be used below -29 Degrees Celsius instead of LTCS?

What is the primary metallurgical difference in Carbon Steel vs LTCS Pipe?

Does ASME B31.3 allow the use of stress ratio for all material grades?

How should I document a Carbon Steel vs LTCS Pipe substitution audit?

Final Assessment on Carbon Steel vs LTCS Pipe

Successfully managing a material substitution involving Carbon Steel vs LTCS Pipe requires a deep understanding of metallurgy and the flexible application of ASME B31.3 standards. While the initial discovery of standard carbon steel in an LTCS-rated system can be alarming, the use of Stress Ratio analysis often provides a safe, code-compliant path to operational readiness without the extreme costs of reconstruction.

As we progress through 2026, the integration of real-time material tracking and advanced stress modeling continues to reduce these errors. However, the human element of engineering oversight remains the final safeguard against brittle fracture in our global energy infrastructure.

📚 Recommended Resources: Carbon Steel

Read these Guides

🎓 Advanced Training