What is an Anti-surge Valve? Functions, Working, and Design Standards

An Anti-surge Valve is a specialized control valve designed to protect centrifugal and axial compressors from the catastrophic effects of surge by rapidly recycling gas from the discharge back to the suction. In the high-stakes environment of 2026 oil and gas operations, the Anti-surge Valve serves as the final line of mechanical defense, ensuring that flow remains above the surge limit line even during emergency shutdowns or process upsets.

Quick Definition

An Anti-surge Valve is a high-speed recycle valve that prevents flow reversal in compressors. It operates by opening quickly to maintain a minimum flow rate, preventing pressure oscillations that can destroy impellers, bearings, and seals. Its primary performance metrics are ultra-fast stroke speeds and high rangeability.

In This Technical Guide

Engineering Knowledge Check: Anti-surge Valve Logic

Question 1 of 5

Complete Course on

Piping Engineering

Check Now

Key Features

- 125+ Hours Content

- 500+ Recorded Lectures

- 20+ Years Exp.

- Lifetime Access

Coverage

- Codes & Standards

- Layouts & Design

- Material Eng.

- Stress Analysis

Primary Functions of an Anti-surge Valve in Compressor Systems

The Anti-surge Valve is not a standard process control valve; it is a safety-critical component designed for Centrifugal Compressor Protection. Its primary function is to modulate the flow by diverting discharge gas back to the suction side when the process demand drops below a critical threshold. By doing so, it ensures the compressor operates within the stable region of its performance map, effectively preventing the flow reversal known as “surge.”

- Preventing Mechanical Damage: Surge causes rapid pressure fluctuations that can lead to catastrophic failure of thrust bearings and dry gas seals.

- Flow Stabilization: During startup and shutdown, the Anti-surge Valve manages the Compressor Map Stability by maintaining minimum flow requirements.

- Thermal Management: By recycling gas through a cooler, the valve prevents the overheating of the gas trapped within the compressor casing during low-flow conditions.

Detailed Working Principle of Anti-surge Valves

The operation of an Anti-surge Valve is dictated by the Anti-Surge Controller (ASC). The controller monitors the flow (differential pressure) and the pressure ratio across the compressor. This data is plotted against a pre-programmed Surge Limit Line (SLL).

Understanding the Surge Limit Line and Control Gap

To provide a safety buffer, engineers establish an Anti-Surge Control Line (ASCL), typically set at a 10 percent to 15 percent margin to the right of the SLL. When the operating point crosses the ASCL, the Anti-surge Valve begins to open. If the operating point moves rapidly toward the SLL, the valve utilizes a “Step Response” or “Fast Opening” logic to dump pressure instantly.

Figure 1: Typical Compressor Performance Map showing the interaction between the SLL and the Anti-surge Valve control margin.

Critical Anti-surge Valve Requirements for Centrifugal Compressors

Due to the volatile nature of surge cycles, which can occur in milliseconds, the Anti-surge Valve must meet stringent performance criteria that far exceed those of standard globe valves.

Pneumatic Actuator Speed and Dead Time

The most vital requirement is the Pneumatic Actuator Speed. According to industry best practices, the valve must be capable of a “Trip to Open” action in less than 2 seconds for large valves, and often less than 1 second for smaller units. Furthermore, the “Dead Time”—the interval between the controller signal and the first physical movement of the plug—must be minimized using high-capacity volume boosters and quick-exhaust valves.

Engineering Note: Compliance with ASME B16.34 for pressure containment and API 617 for centrifugal compressor integration is mandatory for all Anti-surge Valve installations in 2026.

Engineering Design of Anti-surge Valve Components

The Anti-surge Valve is engineered to withstand extreme differential pressures and high-velocity gas flows. Unlike standard control valves, the Recycle Valve Design prioritizes mechanical integrity during rapid cycling. The body is typically a globe style, selected for its ability to house specialized trims that manage energy dissipation.

Noise Reduction and Cavitation Control in Recycle Lines

When an Anti-surge Valve opens, the pressure drop can be immense, leading to supersonic flow velocities and damaging acoustic vibrations. To mitigate this, 2026 designs utilize Noise Attenuation Trim, such as multi-stage labyrinth paths or drilled hole cages. these components break down the pressure drop into smaller stages, keeping noise levels below 85 dBA and preventing vibration-induced fatigue in downstream piping.

Standard Anti-surge Valve Specification and Datasheet Parameters

Specifying the correct Anti-surge Valve requires a deep dive into the compressor’s operating envelope. The following table outlines the critical technical parameters required for a 2026 engineering datasheet.

| Parameter | Requirement | Engineering Basis |

|---|---|---|

| Stroking Speed | Full Open in < 1.5 Seconds | Rapid protection against surge cycles. |

| Failure Position | Fail-Open (FO) | Ensures compressor safety on loss of air/power. |

| Trim Characteristic | Linear or Modified Equal % | Predictable gain for stable control. |

| Shut-off Class | ANSI/FCI 70-2 Class V or VI | Minimizes gas leakage during normal operation. |

| Rangeability | 50:1 or Higher | Precise control at both low and high recycle flows. |

Valve Sizing and Flow Coefficient (Cv) Calculation

The sizing of an Anti-surge Valve is critical. If the valve is undersized, it cannot recycle enough flow to stop a surge; if oversized, the control becomes unstable. The required Cv is typically calculated using the maximum surge flow plus a 20 percent safety margin:

Cvrequired = Qsurge * 1.2 / (N1 * Fp * P1 * Y * [(1 / (Gg * T1 * Z))]0.5)

Note: Where Q is flow rate, P1 is inlet pressure, and T1 is inlet temperature.

Leading Manufacturers of Anti-surge Valves

Selecting a reliable manufacturer is paramount for Centrifugal Compressor Protection. The following vendors are recognized in 2026 for their specialized anti-surge engineering:

Emerson (Fisher)

Known for the FB Series and Whisper Trim technology for high-noise recycle service.

Baker Hughes (Masoneilan)

Offers the 41000 Series with high-speed pneumatic actuation and digital positioners.

IMI Critical (Mogas/CCI)

Specialists in multi-stage DRAG trim technology for severe service pressure drops.

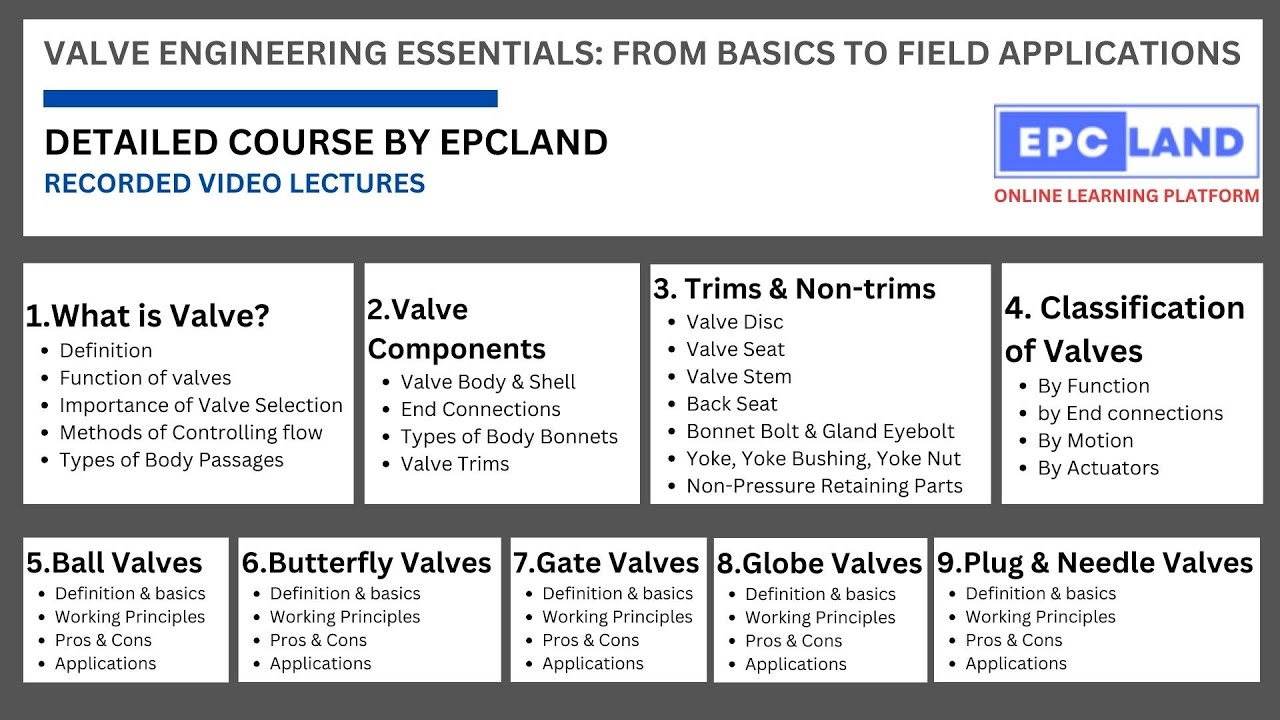

Don’t miss this video related to Valve

Summary: Master Piping Engineering with our complete 125+ hour Certification Course: ……

Anti-surge Valve Sizing Estimator

Use this tool to estimate the required Flow Coefficient (Cv) for your Anti-surge Valve. This calculation includes a standard 20 percent engineering safety factor over the surge flow rate.

Case Study: Optimizing Anti-surge Valve Response in a 2026 LNG Liquefaction Plant

Project Data

- Application: Mixed Refrigerant (MR) Centrifugal Compressor

- Media: Hydrocarbon Mix (Methane, Ethane, Propane)

- Design Pressure: 1250 psig

- Operational Challenge: Frequent trips due to grid instability causing rapid surge cycles.

Failure Analysis

In the initial 2024 audit, the existing recycle valve exhibited a 4.5-second stroke time. During a total plant power loss, the compressor entered surge within 2.1 seconds. The slow Anti-surge Valve response led to high-frequency vibration and premature wear on the dry gas seal faces, costing the facility 450,000 USD in unplanned downtime.

Factory Acceptance Testing (FAT) for high-speed pneumatic actuation.

Engineering Fix

The engineering team replaced the legacy assembly with a high-performance globe valve featuring a Noise Attenuation Trim and a double-acting piston actuator. The instrumentation was upgraded with:

- Dual high-capacity volume boosters for immediate air displacement.

- Digital positioner with “Partial Stroke Testing” capabilities for 2026 reliability standards.

- Quick exhaust valves to dump actuator air in under 0.5 seconds.

Lessons Learned:

Validation of the Pneumatic Actuator Speed must include the “Dead Time” of the entire control loop. By reducing the total response time to 1.2 seconds, the facility eliminated surge-related trips during grid fluctuations, securing the mechanical integrity of the compressor train for long-term 2026 operations.

Frequently Asked Questions: Anti-surge Valve Technology

How do Anti-surge Valve stroke times impact Centrifugal Compressor Protection? +

What is the difference between a recycle valve and a specialized Anti-surge Valve? +

Why is a Fail-Open (FO) configuration required for these valves? +

What role does the Surge Limit Line (SLL) play in valve automation? +

Summary and Conclusion

In conclusion, the Anti-surge Valve is the single most important instrument for the protection of rotating assets in any gas processing facility. From the high-speed Pneumatic Actuator Speed requirements to the complex engineering behind Noise Attenuation Trim, every aspect of the valve must be meticulously specified.

As we move through 2026, the integration of smart digital positioners and advanced Recycle Valve Design continues to enhance plant safety and availability. Ensuring your Anti-surge Valve meets the latest ASME and API standards is not just a regulatory requirement—it is a fundamental necessity for operational excellence.

📚 Recommended Resources: Valve

Read these Guides

🎓 Advanced Training