Comprehensive Guide to Reciprocating Compressor Sizing

Reciprocating Compressor Sizing is a critical engineering process governed by API 618 standards to ensure the reliable delivery of process gases in refineries and chemical plants. In 2026, precision in calculating cylinder displacement and rod loads remains the cornerstone of mechanical integrity and operational efficiency.

What is Reciprocating Compressor Sizing?

Reciprocating Compressor Sizing is the multi-step engineering procedure used to determine the required cylinder bore, stroke, and stage count to meet specific mass flow rates. It involves calculating compression ratios, volumetric efficiency, and brake horsepower (BHP) while ensuring gas rod loads stay within frame limits per API 618 or API 11P.

Technical Knowledge Check: Compressor Sizing

Question 1/5

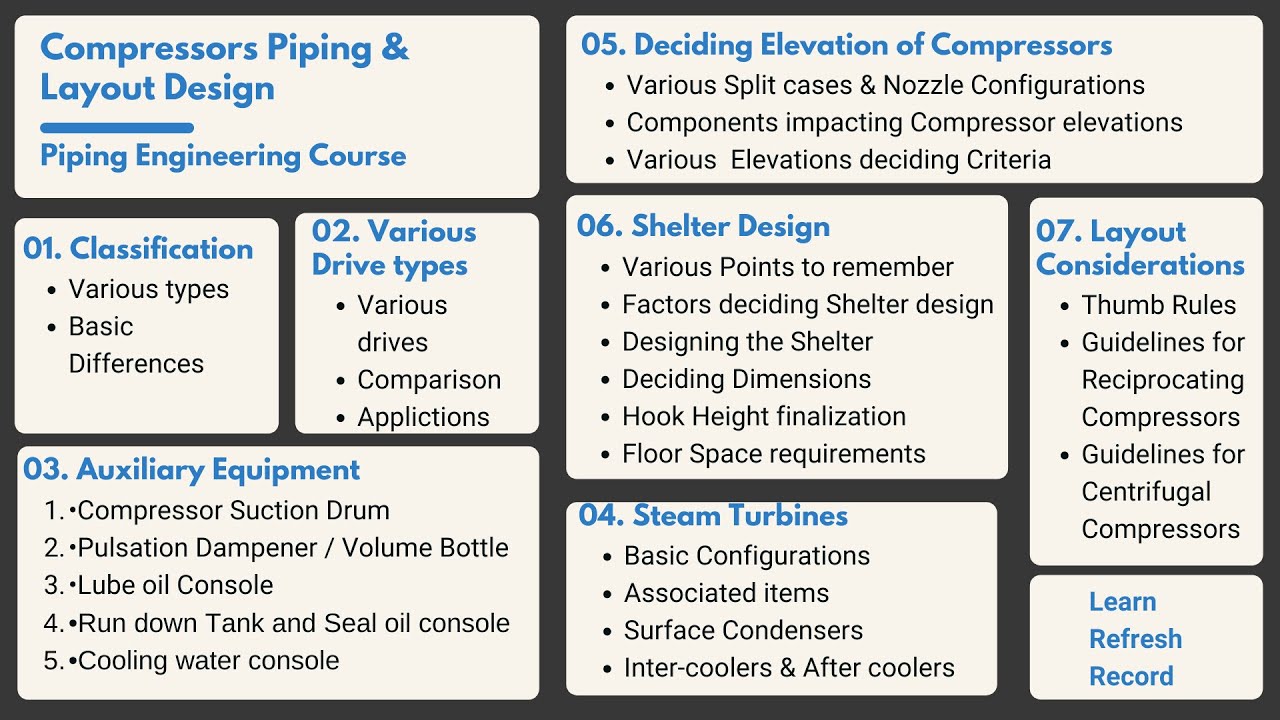

Complete Course on

Piping Engineering

Check Now

Key Features

- 125+ Hours Content

- 500+ Recorded Lectures

- 20+ Years Exp.

- Lifetime Access

Coverage

- Codes & Standards

- Layouts & Design

- Material Eng.

- Stress Analysis

API 618 and ISO Standards for Reciprocating Compressor Sizing

When performing Reciprocating Compressor Sizing, adherence to international standards ensures both safety and performance. The primary benchmark for heavy-duty process industry applications is API 618 (Reciprocating Compressors for Petroleum, Chemical, and Gas Industry Services). This standard defines strict requirements for speed, vibration, and mechanical design. For high-speed applications, engineers refer to API 11P or ISO 13631.

Selecting the Proper Reciprocating Compressor Sizing Methodology

The sizing process is iterative. It begins with the process conditions (mass flow, gas composition, suction pressure, and temperature) and concludes with the selection of a mechanical frame and cylinder bores that can withstand the resulting Gas Rod Loads.

Fundamental Principles of Reciprocating Compressor Sizing

Step 1: Calculate the Compression Ratio (CR)

The compression ratio is the fundamental driver of heat and efficiency. It is calculated by dividing the absolute discharge pressure by the absolute suction pressure. In Reciprocating Compressor Sizing, we aim to keep the CR per stage below 4.0 to manage discharge temperatures.

Step 2: Determine Stages for Reciprocating Compressor Sizing

Multiple stages are required when the total compression ratio exceeds the safe limit of a single cylinder. Staging reduces the discharge temperature and minimizes the required Brake Horsepower (BHP). The goal is to equalize the compression ratio across all stages to balance the load.

Step 3: Calculate Estimated Brake Horsepower (BHP)

Power estimation is vital for driver selection (motor or engine). The BHP is derived from the adiabatic or polytropic head required to move the gas. During Reciprocating Compressor Sizing, a mechanical efficiency of 95 percent is typically applied to the gas power to account for frame losses.

Step 4: Calculate Estimated Discharge Pressure (Psia)

The discharge pressure at each stage must account for pressure drops through intercoolers and pulsation dampeners. Accurate pressure modeling ensures that the final stage meets the process requirement.

Step 5: Calculate Discharge Temperature and Heat of Compression

Excessive temperature can destroy valve plates and piston rings. The discharge temperature is a function of the suction temperature, CR, and the isentropic exponent (k) of the gas. Per API 618, the limit is usually 135 degrees C for most refinery services.

Suction Volumetric Efficiency in Reciprocating Compressor Sizing

Volumetric Efficiency (VE) is perhaps the most critical variable in Reciprocating Compressor Sizing. It represents the ratio of the actual volume of gas taken into the cylinder to the displacement of the piston. Factors such as clearance volume, valve losses, and gas slippage play a significant role.

| Parameter | Standard API 618 | High Speed (API 11P) |

|---|---|---|

| Avg. Piston Speed | 4.0 to 4.5 m/s | Up to 5.5 m/s |

| Valve Velocity | Low (Efficiency focus) | High (Compact focus) |

| Discharge Temp Limit | 135 degrees C | 150 to 165 degrees C |

Step 7: Calculate Required Piston Displacement and Cylinder Bore

Once the VE is determined, the Reciprocating Compressor Sizing requires calculating the required Piston Displacement (PD). This is the total volume swept by the piston per unit of time.

PD = (Actual Flow Rate) / (Volumetric Efficiency)

Note: Actual flow must be converted to suction conditions (P1, T1, Z1).

Evaluate Gas Rod Loads and Frame Ratings

A critical safety check in Reciprocating Compressor Sizing is the gas rod load calculation. This is the force exerted on the piston rod due to the differential pressure across the piston.

Simplified Rod Load Logic:

- Tension Load: (Pdischarge x Areapiston rod side) – (Psuction x Areapiston head side)

- Compression Load: (Pdischarge x Areapiston head side) – (Psuction x Areapiston rod side)

Both values must be lower than the OEM frame rating to prevent catastrophic failure.

Step 8 & 9: Valve Velocity and OEM Data Integration

In 2026, Reciprocating Compressor Sizing software integrates OEM-specific valve dynamics. High valve velocity leads to increased “Stagewise” pressure drops, reducing the overall system efficiency. Proper sizing ensures the gas velocity through the valve lift area remains within conservative limits (typically 2,500 to 3,500 ft/min).

Don’t miss this video related to Reciprocating Compressor Sizing

Summary: Master Piping Engineering with our complete 125+ hour Certification Course: ……

Reciprocating Compressor Sizing Calculator

Estimate the Compression Ratio (CR) and theoretical Discharge Temperature (T2) for your 2026 preliminary sizing study.

Case Study: Reciprocating Compressor Sizing for Hydrogen Refinery Service

Project Data

A major refinery required Reciprocating Compressor Sizing for a Make-Up Hydrogen service with a suction pressure of 250 Psia and a target discharge of 1,200 Psia. The gas contained 98 percent Hydrogen (H2).

Failure Analysis (Initial Design)

The initial single-stage proposal resulted in a compression ratio of 4.8. This led to calculated discharge temperatures exceeding 160 degrees C, far above the API 618 limit of 135 degrees C. Furthermore, the Gas Rod Load exceeded the frame’s structural limit by 15 percent.

Engineering Fix & Final Sizing

The sizing was revised to a 2-stage configuration with intercooling.

- Stage 1: CR of 2.19 (250 to 548 Psia)

- Stage 2: CR of 2.19 (548 to 1200 Psia)

- Result: Discharge temperature dropped to 118 degrees C per stage.

- Integrity: Rod loads were reduced to 70 percent of frame capacity, ensuring a 20-year fatigue life.

Lessons Learned: High compression ratios in low-molecular-weight gases (like Hydrogen) drastically increase heat. Multi-stage Reciprocating Compressor Sizing is non-negotiable for high-pressure ratios to maintain mechanical integrity.

Common Questions on Reciprocating Compressor Sizing

How does Gas Molecular Weight affect Reciprocating Compressor Sizing? ▼

Why is API 618 critical for Reciprocating Compressor Sizing in refineries? ▼

What is the impact of Clearance Volume on Piston Displacement? ▼

How are Rod Load Limits calculated in modern sizing software? ▼

📚 Recommended Resources: Compressor

Read these Guides

🎓 Advanced Training