What is a Fiberglass Pipe Shaver? Working and Specification of Fiberglass Pipe Shavers (2026)

A Fiberglass Pipe Shaver is a precision-engineered machining tool specifically designed to remove the outer layers of Fiber Reinforced Polymer (FRP) or Glass Reinforced Epoxy (GRE) pipes to create a perfectly tapered “scarf” joint for adhesive bonding.

Quick Definition: Fiberglass Pipe Shaver

A Fiberglass Pipe Shaver (also known as a tapering tool) is a specialized device used to shave the external surface of a composite pipe end. By creating a specific taper angle, it ensures a maximum surface area for resin bonding, meeting ASME NM.1 and ISO 14692 standards for high-pressure industrial piping systems in 2026.

Knowledge Check: Fiberglass Pipe Shavers

Question 1 of 5

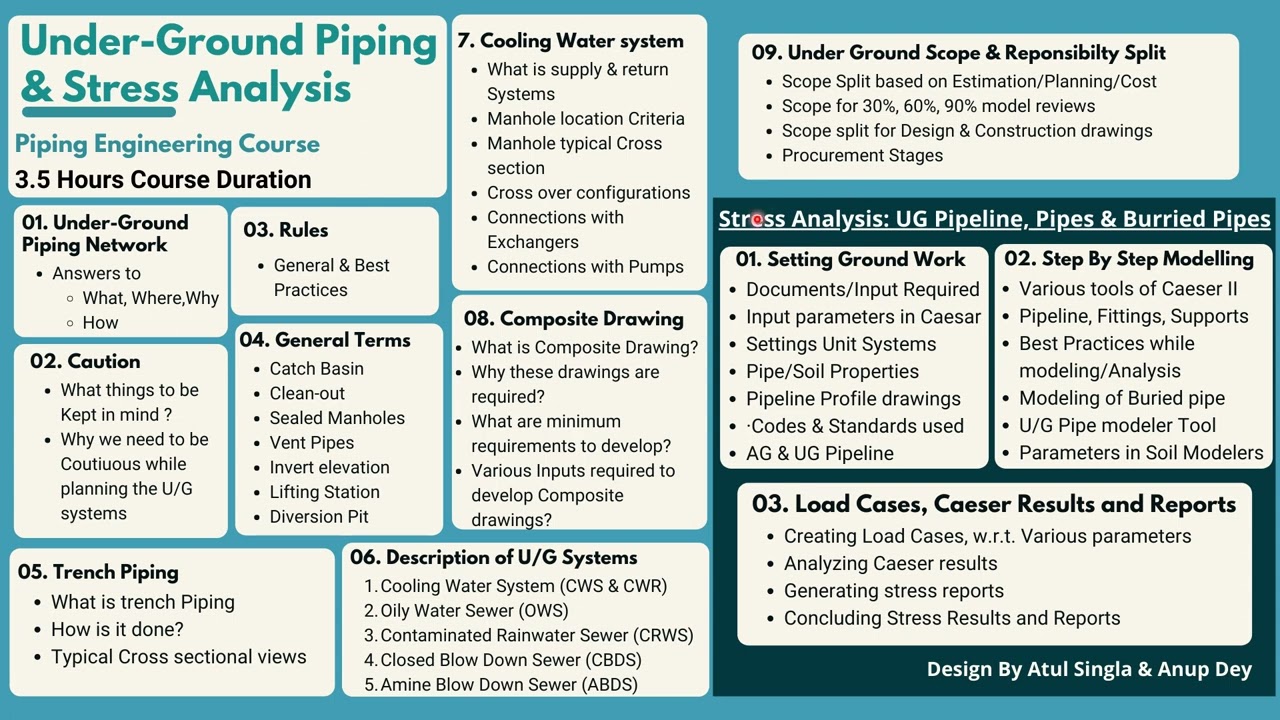

Complete Course on

Piping Engineering

Check Now

Key Features

- 125+ Hours Content

- 500+ Recorded Lectures

- 20+ Years Exp.

- Lifetime Access

Coverage

- Codes & Standards

- Layouts & Design

- Material Eng.

- Stress Analysis

Critical Applications of Fiberglass Pipe Shaver Tools

In the engineering landscape of 2026, the Fiberglass Pipe Shaver has become an indispensable asset for ensuring the structural integrity of composite piping networks. Unlike metallic pipes that rely on thermal fusion, fiberglass systems utilize adhesive bonding, which necessitates a high-precision FRP Tapering Tool to prepare the contact surfaces.

Composite Pipe Joining and Scarfing Prep

The primary role of a Fiberglass Pipe Shaver is to facilitate the “scarf joint” or “taper-to-taper” connection. By removing the resin-rich outer layer and exposing the structural glass fibers at a specific angle, the tool ensures that the adhesive bond can transfer axial loads effectively across the joint, meeting ISO 14692 requirements for high-pressure service.

Industrial FRP Piping Systems

In chemical processing plants, Composite Pipe Joint Preparation is critical for handling aggressive media. A Fiberglass Pipe Shaver allows technicians to match the pipe end geometry precisely to the manufacturer’s coupling specs, preventing “dry spots” or resin-starved areas that could lead to catastrophic failure under 2026 safety protocols.

Fiberglass and Composite Piping Infrastructure

Municipalities are increasingly adopting Fiberglass Pipe Shaver technology for desalination and wastewater treatment. The ability to perform Pipe Scarfing Equipment operations on-site allows for rapid deployment of large-diameter networks without the need for complex factory-prepped ends.

High-Pressure Pipeline Maintenance and Repair

For emergency repairs, a Fiberglass Pipe Shaver enables the creation of a “patch” or “repair sleeve” interface. By using a Mandrel-fed Pipe Shaver, maintenance crews can ensure the repair area is perfectly concentric, which is vital for maintaining the pressure rating of the original pipeline.

Anatomy and Components of a Fiberglass Pipe Shaver Tool

To achieve the precision required for Adhesive Bond Preparation, a professional Fiberglass Pipe Shaver consists of several specialized components engineered for the abrasive nature of glass-reinforced materials.

- Internal Mandrel: The central shaft that inserts into the pipe ID, providing a stable, concentric axis for the Fiberglass Pipe Shaver to rotate around.

- Carbide Cutting Blades: Specialized Pipe End Beveling Tool inserts designed to withstand the high abrasion of glass fibers without dulling prematurely.

- Feed Mechanism: A calibrated lead screw that controls the rate at which the Fiberglass Pipe Shaver moves along the pipe length, ensuring a consistent taper angle.

- Adjustment Gauges: Precision dials that allow the operator to set the depth of the cut and the final outside diameter (OD) of the tapered section.

Step-by-Step Working of Fiberglass Pipe Shavers

Operating a Fiberglass Pipe Shaver involves a sequence of precision maneuvers designed to achieve a high-integrity Composite Pipe Joint Preparation. In 2026, automation features in these tools have significantly reduced human error.

- Internal Alignment: The Mandrel-fed Pipe Shaver is inserted into the pipe. The internal gripping pads are expanded to lock the tool firmly against the pipe wall, ensuring the shaving axis is perfectly parallel to the pipe’s centerline.

- Blade Calibration: The operator sets the Pipe End Beveling Tool depth. This is calculated based on the pipe wall thickness and the required scarf ratio (typically 1:10 or 1:20 as per ASME NM.1).

- The Shaving Process: As the Fiberglass Pipe Shaver rotates, the lead screw advances the carriage. The carbide blades remove the “weathering layer” and structural resin, exposing the glass reinforcement.

- Final Verification: Once the Pipe Scarfing Equipment reaches the pre-set stop, the taper is inspected for uniformity and surface roughness, which is vital for Adhesive Bond Preparation.

Technical Specifications of a Professional Fiberglass Pipe Shaver

Engineers selecting Fiberglass Pipe Shaver units must evaluate specific performance metrics to ensure compatibility with various resin systems like Vinylester or Epoxy.

| Specification Property | Standard Range (2026) | Engineering Impact |

|---|---|---|

| Pipe Diameter Range | 2″ (50mm) to 48″ (1200mm) | Determines tool portability and mandrel sizing. |

| Taper Angle Accuracy | +/- 0.1 Degrees | Critical for high-pressure FRP Tapering Tool joints. |

| Blade Material | Tungsten Carbide (Grade K10) | Resists abrasion from Fiberglass Pipe Shaver operations. |

| Drive System | Electric (110V/220V) or Pneumatic | Pneumatic preferred for “Hot Work” zones. |

Engineering Physics: Taper Geometry

The performance of a Fiberglass Pipe Shaver is governed by the scarf length (L) required to dissipate shear stress in the adhesive. In 2026, we utilize the following simplified geometric relation for setup:

L = (tw – tl) * Rs

Where: L = Scarf Length, tw = Wall Thickness, tl = Land Thickness, Rs = Scarf Ratio

Example: For a 10mm wall pipe with a 2mm land and a 1:10 ratio, the Fiberglass Pipe Shaver must be set to a length of 80mm.

Safety Standards for Operating a Fiberglass Pipe Shaver

Safety is paramount when using Pipe Scarfing Equipment due to the generation of fine composite dust and sharp glass particulates.

- Respiratory Protection: High-efficiency particulate air (HEPA) filtration is mandatory to prevent inhalation of glass fibers.

- Dust Containment: Most 2026 Fiberglass Pipe Shaver models feature integrated vacuum shrouds.

- Spark Prevention: In flammable environments, ensure the FRP Tapering Tool is non-sparking or pneumatically driven.

Fiberglass Pipe Shaver Scarf Length Calculator

Calculate the required shaving length (L) based on your pipe wall thickness and engineering scarf ratio for 2026 standards.

Recommended Shaving Length:

Note: Ensure your Fiberglass Pipe Shaver stop-collar is set to this value before operation.

Don’t miss this video related to Fiberglass Pipe

Summary: This video talks about a course on piping engineering and high covers underground piping and layout, along with stress analysis ……

Industry Leaders: Top 3 Fiberglass Pipe Shaver Systems (2026)

In the high-pressure composite piping market, the tooling is often dictated by the piping system specified. However, for general maintenance and large-diameter field machining, universal options compete with proprietary giants. Below is a breakdown of the three dominant Pipe Scarfing Equipment categories used in 2026.

| Feature | NOV Fiber Glass Systems (Bondstrand) | Future Pipe Industries (Wavistrong) | Universal Split-Frame (e.g., Wachs/Tri Tool) |

|---|---|---|---|

| Primary Tool Series | M-Series (M87XL, M95) | Wavistrong Taper Units | LDSF / HDSF Split Frames |

| Mounting Method | Internal Expanding Mandrel (ID Mount) | Internal Mandrel & Spigot Guide | External Clamping (OD Mount) |

| Diameter Range | 2″ to 40″ (50-1000mm) | 3″ to 24″ (Standard) / Custom 60″ | Unlimited (2″ to 120″+) |

| Best Application | Offshore & Marine High-Pressure Lines | Municipal & Desalination Plants | Heavy Wall Retrofits & Non-Standard Pipes |

| Scarf Precision | High (Matched to Bondstrand Taper) | High (Matched to Wavistrong Lock) | Extreme (CNC Programmable Options) |

NOV Bondstrand

The global standard for offshore oil & gas. Their Fiberglass Pipe Shaver units are legendary for portability. The M-Series uses a unique floating blade holder that adjusts for slight pipe ovality, ensuring a consistent bond line thickness essential for 50+ bar pressure ratings.

Future Pipe (FPI)

Dominating the water sector, FPI’s tooling focuses on speed. Their FRP Tapering Tool kits often include “Go/No-Go” gauges that allow rapid field verification of the land thickness, crucial for meeting tight desalination project schedules in 2026.

Universal OD Machines

When proprietary tools aren’t available or when dealing with “out-of-spec” thick-wall pipes, OD-mounted split frames are the engineering solution. While heavier, they offer absolute rigidity and can machine complex compound tapers that handheld mandrels cannot achieve.

Fiberglass Pipe Shaver Failure Case Study: High-Pressure Desalination Line

Project Data (2026)

- Facility: SWRO Desalination Plant, UAE

- Material: 36-inch Glass Reinforced Epoxy (GRE)

- System Pressure: 70 Bar (1015 PSI)

- Primary Issue: Joint leakage during hydro-test

Failure Analysis

Forensic inspection of the failed Fiberglass Pipe Shaver joints revealed non-uniform taper angles. Investigation showed that the field crew used a manual FRP Tapering Tool without a calibrated mandrel, leading to “chatter marks” and a “stepped” surface rather than a smooth 1:10 scarf. This created localized stress concentrations and resin-poor voids.

The Engineering Fix

The contractor replaced the manual units with a Mandrel-fed Pipe Shaver equipped with precision tungsten carbide blades. A digital Fiberglass Pipe Shaver depth gauge was utilized to ensure a tolerance of +/- 0.05mm on all subsequent Composite Pipe Joint Preparation.

Lessons Learned

- Manual Pipe Scarfing Equipment is unsuitable for diameters >12″ in high-pressure service.

- Blade sharpness must be checked every 10 shaves to prevent fiber tearing.

- Strict adherence to ISO 14692 surface roughness values is non-negotiable for 2026 projects.

Frequently Asked Questions: Fiberglass Pipe Shaver Operations

How does a Mandrel-fed Pipe Shaver improve joint reliability?

What is the optimal surface roughness for Adhesive Bond Preparation?

Can a Pipe Scarfing Equipment unit handle GRE and GRP pipes?

How do 2026 standards affect FRP Tapering Tool selection?

The Future of FRP Tapering in 2026

Precision prep is the backbone of composite engineering. As we move through 2026, the reliance on the Fiberglass Pipe Shaver will only increase as industrial sectors shift from heavy alloys to lightweight, corrosion-resistant FRP. By mastering the working and specification of these tools, engineers ensure that every adhesive bond is a permanent, high-performance solution.

Always prioritize tool calibration and safety protocols when operating professional Pipe Scarfing Equipment.

📚 Recommended Resources: Fiberglass Pipe

Read these Guides